|

Back in 2020, the IMO 2020 regulations, which reduced the global upper limit on the sulphur content of ships' fuel oil from 3.5% to 0.50%, posed significant challenges for the marine industry.

Beyond compliance, ship operators faced difficulties stemming from very-low-sulphur fuel oil (VLSFO) blends. Key issues included poor cold-flow properties, short shelf life, sludge formation, stability concerns, and, most critically, liner scuffing in large two-stroke engines.

Liner scuffing, a significant contributor to main engine damage, was initially thought to be unrelated to fuel quality, engine maintenance, or fuel compatibility. However, further investigations identified interactions between VLSFO blends and cylinder oils as the root cause.

Cylinder oil plays a vital role in maintaining engine health through:

With the introduction of VLSFO, oil majors and original equipment manufacturers (OEMs) recommended a shift from high base number (BN) cylinder oils (70/100 BN) to lower BN oils (40 BN). This change reduced calcium-based additives, which are crucial for neutralisation and detergency, leading to increased deposit formation and, in some cases, resulting in liner scuffing.

Addressing liner scuffing

By mid-2020, OEMs introduced Category II (CAT II) cylinder oils designed to enhance cleaning and deposit control. Alongside improved cylinder lubrication practices, close monitoring of liner wear helped mitigate scuffing issues. Some operators successfully adopted blend-on-board techniques, enabling customisation of cylinder oil properties such as neutralisation and detergency. This flexibility significantly reduced engine issues, demonstrating the importance of tailored cylinder lubrication strategies.

VLSFO also exhibited poor cold-flow properties, leading to wax precipitation and reduced stability in colder climates. These challenges emphasised the importance of proper fuel storage, handling, and management practices to maintain fuel integrity and engine reliability.

The evolving landscape of marine fuels, driven by regulatory and environmental pressures, demands better understanding and management of both traditional fossil fuels and emerging alternatives like biofuels. International standard ISO8217:2024 is seen as a major step forward in terms of setting specifications for marine fuel quality.

Biofuel alternatives

With the industry looking to decarbonise, and a view to introducing low- to zero-carbon fuels, biofuels such as methanol and various fatty acid methyl esters (FAME) blends currently account for approximately 1% of the fuel mix. The more traditional fossil fuels are continuing to satisfy the day-to-day demand in terms of fuels supplied to vessels at this time.

Among these, cashew nutshell liquid (CNSL) and FAME have been explored as drop-in fuel options alongside several other alternatives. CNSL is a renewable resource with potential as a ready drop-in fuel. Its key phenolic compounds include:

While CNSL improves lubricity and energy content, its limitations include high acidity, poor combustion properties, and corrosive tendencies.

In 2022, CNSL-blended fuels caused operational challenges, particularly in the Amsterdam-Rotterdam-Antwerp (ARA) region. Reported issues included:

These issues were primarily attributed to CNSL's high acidity leading to corrosion of fuel systems and polymerisation tendencies, which in turn led to sludge formation. With regards to combustion characteristics, CNSL exhibited late ignition and extended period of combustion leading to after burning, high exhaust temperatures, carbon deposits in the exhaust system and less power developed. Even at low concentrations, CNSL requires careful management to avoid significant impacts on engine components.

Thermal decarboxylation — converting anacardic acid into cardanol, reducing acidity and increasing stability — and distillation — separating cardanol from other components to create a product better suited for fuel blending — can be applied to enhance CNSL characteristics.

While these treatments are known to improve CNSL's usability, further research is necessary to fully understand its long-term effects on engine performance and reliability.

FAME is the most widely used biofuel in marine applications. Although relatively new to the shipping industry, its extensive use in road transportation provides valuable insights.

Meanwhile, between 2023 and 2024, the use of used cooking oil methyl ester (UCOME) increased significantly.

Many operators tested B100 blends to prepare for regulatory requirements, including the GHG Strategy, Energy Efficiency Design Index (EEDI), Carbon Intensity Indicator (CII) and Energy Efficiency Existing Ship Index (EEXI). In 2024, at Veritas Petroleum Services (VPS), we noticed an uptake of B30 blends, a rise considered consistent with MARPOL Annex VI, Regulation 18.3.2, which mandates verification of NOx impacts for blends exceeding 30%.

The impending implementation of FuelEU Maritime is expected to further boost the adoption of biofuel blends.

Operational considerations for FAME blends

There are some important operational considerations to consider for FAME blends. First, it has a tendency to absorb water, potentially leading to microbial growth. Proper storage and a first-in, first-out approach are critical to address this.

Second, at higher concentrations (B100, for example), there could be material compatibility issues. Third, FAME's solvency can dissolve deposits in fuel systems, potentially clogging filters. Lastly, due to its limited stability, FAME should be consumed promptly.

However, despite these considerations, when managed correctly, FAME blends can be used effectively alongside conventional fuels without significant operational issues.

The evolution of marine fuels, from VLSFO to alternative options like CNSL and FAME, underscores the need for comprehensive fuel and lubrication management strategies.

Addressing challenges such as liner scuffing, cold-flow properties, and compatibility is critical to maintaining engine reliability and operational efficiency. With increasing regulatory demands, the marine industry must continue to innovate and adapt to ensure a sustainable and efficient future.

|

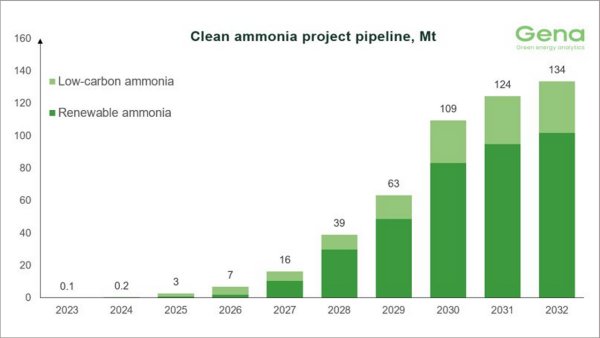

Clean ammonia project pipeline reaches 145 MMT by 2034, but delivery concerns mount

GENA Solutions reports 325 tracked projects, though over 70 have been frozen in 20 months. |

|

|

|

||

|

Peninsula highlights supply chain strength amid Strait of Hormuz closure

Marine fuel seller emphasises reliability as geopolitical disruption reshapes global bunker markets. |

|

|

|

||

|

World Shipping Council backs EU maritime strategies but calls for faster trade simplification

Industry body supports port security and decarbonisation measures while urging action on customs barriers. |

|

|

|

||

|

Anemoi and Lloyd’s Register call for unified approach to wind propulsion performance verification

Anemoi Marine Technologies and Lloyd’s Register publish paper advocating alignment of verification methodologies. |

|

|

|

||

|

Smyril Line's methanol-ready ro-ro launched in China

First of two 3,300 lane-metre vessels floated out for Faroese operator. |

|

|

|

||

|

ICS webinar explores regulatory framework for nuclear-powered merchant ships

Industry experts discuss the timeline and challenges for adopting nuclear propulsion in the commercial shipping sector. |

|

|

|

||

|

Oilmar DMCC seeks senior bunker trader for Dubai office

Dubai-based energy trader recruiting for Middle East, Indian subcontinent and Africa trade flows. |

|

|

|

||

|

Oilmar DMCC seeks bunker traders for Singapore office

Dubai-based trader recruiting mid-level and senior professionals to expand Asia-Pacific marine fuels operations. |

|

|

|

||

|

ClassNK updates EU shipping emissions guidance for LNG-fuelled vessels

Japanese classification society releases revised FAQs addressing methane slip measurement procedures. |

|

|

|

||

|

Bureau Veritas delivers first 15,000-teu methanol dual-fuel container ship for CMA CGM

Classification society completes delivery of CMA CGM Monte Cristo built by DSIC Tianjin. |

|

|

|

||

| Methanol as a marine fuel | Steve Bee, VPS [News & Insights] |

| Is your vessel fully protected from the dangers of poor-quality fuel? | Steve Bee, VPS [News & Insights] |

| ISO 8217:2024 'a major step forward' | Steve Bee, VPS [News & Insights] |

| ISO 8217 formula 'not suitable' for gauging FAME fuel energy content: VPS [News & Insights] |

| VPS performs first methanol bunker quantity survey [News & Insights] |