SEA-LNG, the industry coalition advocating for LNG as a marine fuel, has released a report which posits that LNG is "the only viable fuel" for shipping to reach IMO's 2030 emissions reduction target.

It argues that LNG-fuelled vessels are "zero-emissions on the water today" and offer a clear route to IMO 2050 thanks to carbon-free liquefied bio-methane (

LBM) and liquefied synthetic methane (

LSM), which can be adopted by LNG-fuelled vessels and LNG infrastructure.

Risk of waiting for 'utopian solution'

The report affirms that waiting for a "utopian solution" risks locking the maritime industry into conventional oil-based marine fuels for years, if not decades, to come.

As things stand, LNG-fuelled vessels currently emit virtually no sulphur oxides (SOx) while dramatically limiting emissions of nitrogen oxides (NOx). LNG also virtually eliminates particulate matter, including black carbon or soot.

In terms of greenhouse gas (GHG) emissions, whilst carbon dioxide (

CO2) pollution takes place during LNG combustion, it is still considerably lower than those of other fossil fuels. However, leakage of methane - also known as '

methane slip' - from the engine, has always been an additional concern with LNG.

According to

a recent study by Sphera, the absolute well-to-wake emissions reduction benefits for gas-fuelled engines today compared with HFO-fuelled ships are between

14 to

21 percent for two-stroke slow-speed engines, and between

7 to

15 percent for four-stroke medium-speed engines.

This, SEA-LNG suggests, means LNG will "likely" meet the IMO 2030 decarbonisation target for newbuild vessels when combined with Energy Efficiency Design Index (EEDI) improvements to ship design.

Efforts to reduce methane slip

Addressing the issue of methane slip, SEA-LNG notes that engine manufacturers recognise it as an issue for certain types of internal combustion engines, but

not all.

Moreover, Wärtsilä states methane slip from its dual-fuel engines has been slashed by

75 percent over the past 25 years, whilst WinGD recently announced a technology improvement that is said to reduce methane slip in its two-stroke low-pressure internal combustion engine by

50 percent.

"Unfortunately, the recently released IMO 4th Study on GHG Emissions relies in part on 2018 and prior data, therefore it does not fully recognize the aggressive work that has been done in the area of slip," SEA-LNG says.

Zero-emission vessels already on the water

The coalition stresses that the pathway to a decarbonised maritime industry has already been demonstrated through the use of LBM and, in due course, LSM as drop-in fuels. In June 2020, the dry bulk carrier

Viiki was bunkered with

100 percent renewable LBM; and later this year,

Wessels Marine will be piloting the use of

LSM in its LNG-fuelled container feeder-ship

Wes Amelie. The LSM is to be supplied from a new liquefaction plant being built at Audi's power-to-gas factory in north Germany.

These fuels can be transported, stored and bunkered in ports utilising existing LNG infrastructure.

A

CE Delft study commissioned by SEA-LNG concludes that LBM and LSM are scalable solutions for the maritime sector, with estimated global supplies potentially exceeding the future energy demand of the global shipping fleet. It also says LBM and LSM will likely be commercially competitive relative to other low- and zero-carbon fuels.

This analysis is supported by a recent

IEA report on the outlook for biogas and biomethane, which concludes that feedstocks available for sustainable production of biogas and biomethane are huge, but that only a fraction of this potential is used today.

Alternative solutions 'unlikely to be ready for decades'

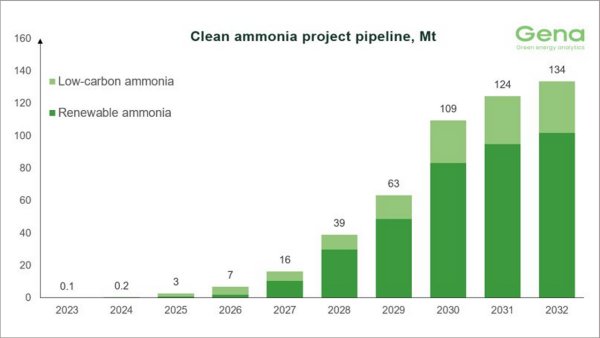

Discussing

hydrogen and

ammonia as alternative solutions, SEA-LNG points out that hydrogen and ammonia fuel storage and propulsion systems are at low technology maturity levels.

Liquid hydrogen has a low energy density, needs to be contained at extremely low temperatures (-251 degrees Celsius), requires large storage tanks and specialised materials. As a fuel it can only be purged with helium, which creates another level of complexity and costs.

Ammonia combustion in an internal combustion engine can produce significant emissions of nitrous oxide (N2O) - a greenhouse gas with a global warming potential 265-298 times greater than CO2 on a 100-year basis. It also produces NOx.

Ammonia slip remains an issue to be quantified and addressed. Because of its narrow flammability range when used in an internal combustion engine, ammonia requires an undetermined percentage of pilot fuel with potential implications for GHG emissions.

Furthermore, there has been no comprehensive well-to-wake analysis performed on any of these alternative fuels as there has on LNG.

High infrastructure costs of alternative solutions

Another critical factor in terms of putting hydrogen and/or ammonia on the water by 2030 will be the development of the associated fuel-supply chains and bunkering infrastructure.

According to a recent

UMAS / Energy Transition Commission study, of the

$1-1.4 trillion investment needed to reduce shipping's GHG emissions by 50 percent by 2050,

87 percent of the cost will be needed to construct the land-based infrastructure and production facilities for low carbon fuels, whilst only 13 percent relates to ships themselves.

There is, as yet, little evidence that other industries are looking to adopt ammonia as a viable future fuel option, thus infrastructure costs may be borne entirely by the shipping industry if ammonia were chosen as the dominant fuel.

Growth of LNG infrastructure

The report notes that LNG is a global commodity with 21 countries exporting to 42 importers.

The bunkering infrastructure to support LNG as a marine fuel continues to grow. LNG bunkering facilities are now established in around

1185 ports and under development in

90.

Ship-to-ship bunkering is also rising. In early 2019 there were just six LNG bunkering vessels in operation; five in Europe and one in North America. As of July 2020, this has grown to

13 with a further

28 on order and/or undergoing commissioning.

In terms of LNG vessels as an investment, LNG marine fuel is said to currently deliver the best return on investment on a net present value (NPV) basis over a conservative 10-year horizon compared with low-sulphur fuel oil, with paybacks varying from less than one year to five years. Also, CAPEX for LNG engines, fuel systems and storage tanks continues to decrease.

"LNG is easy to transport, poses minimal risk to marine environments, has a low flammability range and is non-toxic. Effective regulations, standards and guidelines for safe operations are widespread, and LNG has been shipped around the world for 50 years without any major incidents at sea or in ports," SEA-LNG asserts.