MAN Energy Solutions has announced that its ME-LGIA (Liquid Gas Injection Ammonia) engine has successfully operated at 100% engine load for the first time during tests conducted at its Research Centre Copenhagen (RCC). This achievement marks a notable advancement in the company's ongoing efforts to develop ammonia-fuelled marine engines.

The testing process commenced in November 2024 and has been characterised by a careful and safety-oriented approach, according to Ole Pyndt Hansen, Head of Two-Stroke Research & Development at MAN Energy Solutions. "We began full-scale testing in November 2024 and have since proceeded in a cautious and safety-first way," he stated. The engine has now been tested on ammonia fuel across a load range from 25% to 100%, leading to the validation of the ammonia fuel-injection system throughout the entire load curve, with diesel-pilot amounts recorded in alignment with the company's targets.

In addition to achieving full engine load, the company claims that the positive emissions and performance characteristics observed during earlier single-cylinder tests have been confirmed in full-scale engine operations. MAN Energy Solutions asserts that its proprietary selective catalytic reduction (SCR) technology functioned effectively across all test loads, treating exhaust gases accordingly while ensuring that all supply and safety systems performed as expected.

Looking ahead, the next stages of testing will emphasise enhancing performance and optimising emissions, focusing on the injection and SCR systems, as well as refining control strategies. Christian Ludwig, Head of Global Sales & Promotion for the Two-Stroke Business at MAN Energy Solutions, remarked on the engine's power take-off (PTO) capability. He explained that "the ME-LGIA concept is based on the diesel-cycle combustion principle, which makes it eminently suitable for PTO."

Prior simulations of the PTO capabilities on the ammonia engine yielded favourable results, and Ludwig expressed satisfaction at seeing these outcomes replicated in real-world testing. The company intends to provide PTO support for the ME-LGIA equivalent to that of its other diesel-cycle engines within its low-speed portfolio.

|

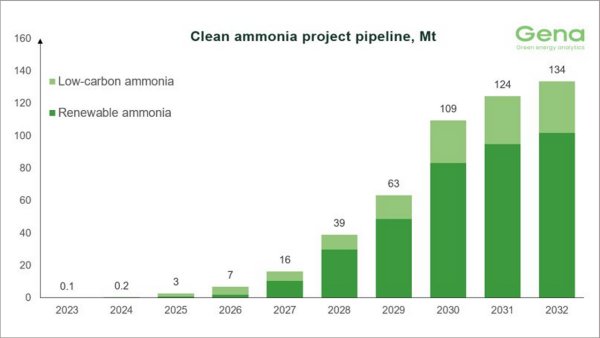

Clean ammonia project pipeline reaches 145 MMT by 2034, but delivery concerns mount

GENA Solutions reports 325 tracked projects, though over 70 have been frozen in 20 months. |

|

|

|

||

|

Peninsula highlights supply chain strength amid Strait of Hormuz closure

Marine fuel seller emphasises reliability as geopolitical disruption reshapes global bunker markets. |

|

|

|

||

|

World Shipping Council backs EU maritime strategies but calls for faster trade simplification

Industry body supports port security and decarbonisation measures while urging action on customs barriers. |

|

|

|

||

|

Anemoi and Lloyd’s Register call for unified approach to wind propulsion performance verification

Anemoi Marine Technologies and Lloyd’s Register publish paper advocating alignment of verification methodologies. |

|

|

|

||

|

Smyril Line's methanol-ready ro-ro launched in China

First of two 3,300 lane-metre vessels floated out for Faroese operator. |

|

|

|

||

|

ICS webinar explores regulatory framework for nuclear-powered merchant ships

Industry experts discuss the timeline and challenges for adopting nuclear propulsion in the commercial shipping sector. |

|

|

|

||

|

Oilmar DMCC seeks senior bunker trader for Dubai office

Dubai-based energy trader recruiting for Middle East, Indian subcontinent and Africa trade flows. |

|

|

|

||

|

Oilmar DMCC seeks bunker traders for Singapore office

Dubai-based trader recruiting mid-level and senior professionals to expand Asia-Pacific marine fuels operations. |

|

|

|

||

|

ClassNK updates EU shipping emissions guidance for LNG-fuelled vessels

Japanese classification society releases revised FAQs addressing methane slip measurement procedures. |

|

|

|

||

|

Bureau Veritas delivers first 15,000-teu methanol dual-fuel container ship for CMA CGM

Classification society completes delivery of CMA CGM Monte Cristo built by DSIC Tianjin. |

|

|

|

||

| Air Liquide and Vopak to collaborate on ammonia project in Singapore [News & Insights] |

| Wärtsilä launches Ammonia Fuel Supply System [News & Insights] |

| Bunker Holding and NeoGreen Hydrogen sign MoU for green ammonia and synthetic fuels [News & Insights] |