The

exhaust gas recirculation (EGR) solution being developed by

MAN Diesel & Turbo with the support of

Alfa Laval is "proving its potential" aboard two A.P. Moller-Maersk vessels, Alfa Laval says.

Between the

Alexander Maersk and the

Maersk Cardiff, nearly 3,500 hours of EGR operation have been logged to date. These seagoing installations, which involve water cleaning with Alfa Laval's PureNOx, show why EGR is at the forefront of Tier III NOx abatement – and how fuel can be saved in Tier II operation.

EGR, which involves the recirculation of exhaust gas, is one of two technologies being developed to meet Tier III NOx limits without resorting to liquefied natural gas. Unlike

Selective Catalytic Reduction (SCR), which is an after-treatment technology that removes NOx with the help of a catalyst, EGR is integrated into the engine and prevents the formation of NOx during combustion.

The advantages of EGR can be seen clearly in installations aboard two container vessels. The Alexander Maersk, a vessel of 1092 TEU whose MAN B&W 7S50MC engine was retrofitted with an EGR prototype in 2010, has spent more than 2,200 hours operating at 50% NOx reduction over today’s basis emission level. Lessons learned in this installation have gone into the 4500 TEU newbuild Maersk Cardiff, whose EGR-equipped engine is fully compliant with Tier III and also well past the 1000-hour operating mark.

"Alfa Laval is proud to be part of these pioneering EGR installations, where our PureNOx has the vital role of cleaning the wash water in the wet scrubber," said Alfa Laval’s

Kristina Effler, Business Manager, Water Treatment Exhaust Gas Emissions. "No other vessel has EGR installed and operating reliably at Tier III. Moreover, it has been possible to demonstrate substantial fuel savings at Tier II."

Tier III NOx limits

As determined at the recently held MEPC66 meeting, Tier III air pollution regulations will require the reduction of NOx emissions by 80% from existing Tier I limits during operation in Emission Control Areas (ECAs). This will apply to marine diesel engines of over 130 kW output power and installed from 1 January 2016 onwards, except for the engines of certain recreational vessels. At present, both North American coastal waters and the US Caribbean Sea are defined as NOx ECAs.

Tier III compliance with Tier II savings

The ability to save fuel in addition to complying with Tier III NOx limits is of vital interest to ship operators as they plan for 2016. A fuel-optimized Tier II operating mode, which facilitates an approximate 4 g/kWh reduction in fuel consumption at partial load, was introduced by MAN Diesel & Turbo with the two-stroke

MAN B&W 6S80ME-C9 engine in 2012.1 This is the engine now installed aboard the Maersk Cardiff, where it is operated entirely by the crew and has logged nearly 350 hours in this mode.

The availability of Tier II savings is important for cost-sensitive operators as they weigh the impact of NOx abatement choices. While SCR entails a slightly lower investment, the amount of consumables and maintenance puts its operating costs at 7-10% of the fuel costs. EGR on the other hand, with no catalyst to maintain and the ability to operate in fuel-optimized Tier II mode, has an operating cost of just 4-6% of the fuel costs in Tier III mode.

"EGR is the only NOx abatement technology that offers fuel savings in addition to Tier III compliance. As such, it is the only technology that will offset the initial investment over time," said Effler. "The savings are more than theoretical, because they can be seen first-hand aboard the Maersk Cardiff."

Investment vs. operating costs of NOx abatement alternatives

| Alternative |

Investment cost per KW

installed power |

Operating cost as a

percentage of fuel costs |

| LNG |

EUR 900-1300 |

N/A |

| SCR |

EUR 30-100 |

7-10% |

| EGR |

EUR 45-60 |

4-6% |

Data provided by Alfa Laval

Maintenance and crew members

Costs, of course, are not the only factor in choosing a NOx abatement solution. Ship operators are also concerned about the size of the installation and the requirements it will place on the crew. Here as well, EGR offers substantial advantages over SCR, according to Effler.

"An EGR system is compact, because nearly everything – including the water cleaning – is integrated into the engine itself. Compare this to an SCR system, where significant engine room space is needed for the reactor and other components," Effler explained. “Likewise, EGR is fully automated and has no filling elements to clean or replace, so it requires very little from the crew."

The importance of easy maintenance was confirmed by

Kurt Larsen, Chief Engineer aboard the Alexander Maersk. "Today the workload for the crew is big enough already, so it’s essential that there isn’t yet another system to maintain frequently," he said. "The potential of EGR seems good in terms of achieving a low-maintenance system."

Consistency as engine load changes

Another prominent operator concern is reliability, especially in today’s world of varying engine loads. An SCR system has a critical minimum exhaust gas temperature for urea injection, as well as a maximum temperature, beyond which the NOx reduction is inefficient.

EGR, by contrast, is effective instantly and requires no warming up of the exhaust gas. Nor is it sensitive to engine load fluctuations, as verified aboard the Alexander Maersk. "There has been no effect whatsoever when changing engine load,” said Chief Engineer Larsen. "The EGR system has run without any problem and the emission reduction performance has not been affected."

The role of PureNOx

What EGR does depend on is the effective cleaning of the wash water in the wet scrubber, which operates in a closed loop. Since marine engines employ a variety of fuels, various combustion products with qualities harmful to the engine are formed. These products are effectively removed by Alfa Laval’s PureNOx, a complete water treatment system based on high-speed centrifugal separation.

"PureNOx keeps soot and other compounds from the exhaust gas from accumulating in the scrubber," Effler explained. "It safeguards efficiency, reduces maintenance and prolongs the service life of engine components by protecting them against corrosion. In addition, PureNOx enables the discharge of excess water in accordance with IMO criteria."

Using centrifugal separation to clean the wash water ensures the highest possible efficiency and stability, Alfa Laval says. Yet the space requirements and operating costs are very low. "It’s difficult for other technologies to compete in efficiency at such a low operating cost," said Effler. "Alfa Laval has developed a separator that is tailor-made for cleaning scrubber wash water, which is a tricky and difficult task – especially for anyone lacking our core separation expertise."

With PureNOx as an integral part, the EGR system functions well under all operating conditions, as witnessed aboard the Alexander Maersk and Maersk Cardiff. "Between these two vessels, PureNOx has shown its capabilities in nearly 3500 hours of successful EGR operation," Effler said.

Next steps for EGR and PureNOx

As the Alexander Maersk and Maersk Cardiff continue to sail, additional PureNOx systems have been delivered to

Chevron Corporation for EGR on two lighter newbuilds powered by

MAN B&W 6G70ME-C9.2 engines. A further delivery has also been scheduled to Mitsui Engineering & Shipbuilding. Meanwhile, Alfa Laval is looking ahead.

"We are actively pursuing new possibilities, such as the potential of combining the EGR water cleaning system with that of a wet SOx scrubber," commented Effler. "What we’ve seen aboard the Alexander Maersk and Maersk Cardiff is exciting, and we on the PureNOx team expect further exciting developments as 2016 approaches."

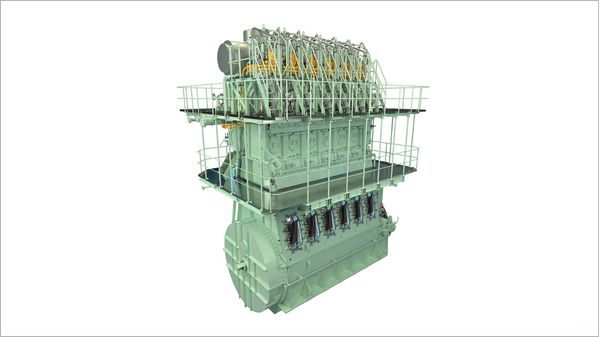

Image: Alexander Maersk.